DRAW DOWN

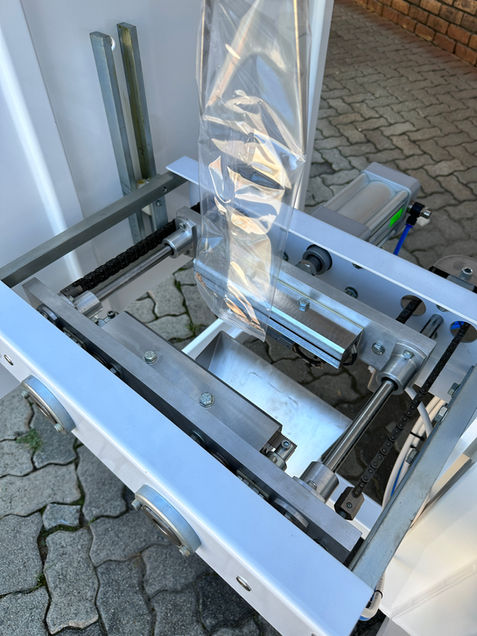

FORM, FILL & SEAL MACHINES

Form, fill and seal machine with volumetric filler.

Form, fill and seal machine with auger filler.

Form, fill and seal machine with liquid filler.

1

Choose your model

We have three models available for our draw down form, fill and seal machines: these are 180, 250 and 300. Each is designed with slight differences to efficiently package various product weights and bag widths.

Our 180 machine can pack up to 500 grams and a bag width of 150.

Our 250 machine can pack up to 1.5 kilograms and a bag width of 220.

Our 300 machine can pack up to 2.5 kilograms and a bag width of 270.

Please note that the pack weight capacity depends on the product density.

2

Choose your filler

2.1 Our draw down form, fill and seal machine with volumetric filler packages free-flowing products such as snack food, rice, beans, sugar, salt, maize, peanuts, bird seed, dog pellets, and more.

2.2 Our draw down form, fill and seal machine with auger filler dosing head packages powder products such as spices, coffee, milk powder, cake mix, coffee creamer, and more.

2.3 Our draw down form, fill and seal machine used with a multi-head weigher can be used for an accurate high speed weighing operation of snacks, chips, chicken portions, dried fruit, and more.

2.4 Our draw down form, fill and seal machine used with a liquid filler for a wide variety of liquid products.

3

What's included?

-

1 complete bag former assembly.

-

PLC controls for accuracy and operator convenience.

-

Touch screen control panel.

-

Constant heat or impulse sealing system, suited to the type of packaging material you operate with.

-

Reel holders with quick packing film reel replacement and tracking adjustment.

-

A volumetric or auger filler with 90 litre hopper.

-

3 cup volumetric dispensing system with flaps or skid plate (not used for auger fillers).

-

Delivery chute.

-

Safety guarding and emergency stop button.

-

A consumable spares start up kit.

4

Optional Extras

-

A bag lifter

-

Bag perforators

-

Date or batch coding: Cost-effective hot foil date coder / Foil or ink jet programmable.

-

Print registration

-

Additional volumetric cups

-

Additional bag former sub-assembly

-

Cut and count facility for strip packing

-

Round hole punch or euro slot

-

A gas flush

-

Static eliminators

-

Any additional consumable spares required

-

Gusseting

5

What To Do Next

Want to sit down and chat with us?

+2711 792 1835

Browse some pictures of our Draw Down Form, Fill and Seal machines below.